Type Model

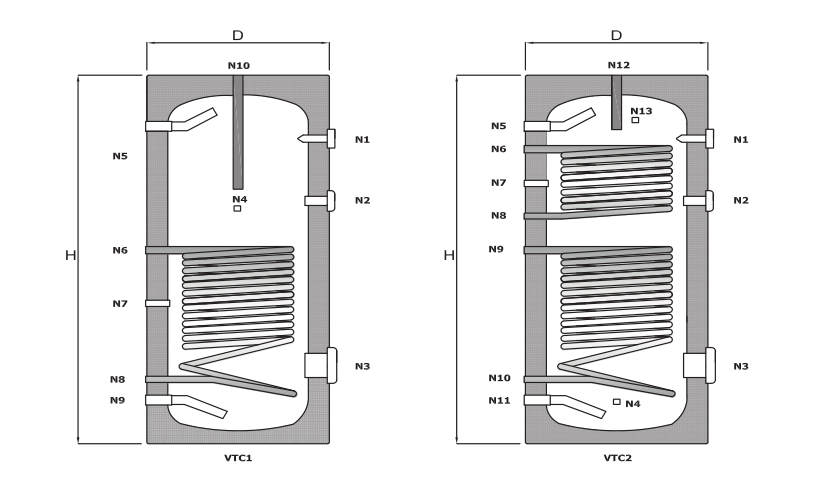

Single coil heat exchanger VTC1

Double coil heat exchanger VTC2

Storage tanks with fixed coil heat exchangers for both circuits for use of heating and solar system. The long large

surface of coils allows efficiently spread of energy along the tank producing domestic hot water and avoiding cold

zones.The base of enamel is, free boron and silisium and hygienically complies with European standards.

Specification

- Material of tank Low carbon hot rolled steel plate DIN EN 10111-98 DD 11

- Welding As per DIN EN 287-1

- Cleaning of steel Chemical washing

- Internal protection Enamel coating, thickness 200-250µm

- Extra Protction Magnesium rod

- Max working temp 95 °C

- Insulation material Free HCFC Polyurethane, density 44 kg/m³

- Insulation thickness 50mm PU for 200-600 lit

80mm Foam Soft PU for 800-3000 lit - Outer jacket Artificial Leather Cover, ( painted steel cover is upon request)

- Max working pressure 10 bar

- Testing pressure 13 bar

- Electrical backup Max. 45 kw (3x15 kw), 380V without thermostats

( upon request ) - Heat exchanger Steel pipe type EN 10217-1, 25 bar @ 95 °C

- Warranty 5 years

- Standard Comply with DIN 4753 and EN 12897 specifications

| Model | VTC1 / VTC2 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Effective capacity,lit | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 | |

| Total Height(H),mm | 1320 | 1210 | 1450 | 1800 | 2040 | 2100 | 2070 | 2300 | 2230 | 2220 | 2540 | |

| Total Dia.(D),mm | 590 | 700 | 750 | 750 | 750 | 900 | 1000 | 1120 | 1260 | 1460 | 1460 | |

| Net weight,kg | VTC1 | 94 | 123 | 153 | 211 | 219 | 262 | 285 | 456 | 530 | 670 | 810 |

| VTC2 | 109 | 143 | 169 | 231 | 247 | 290 | 323 | 476 | 575 | 755 | 895 |

N.B. Storage tank capacity up to 7000 Lit is upon request

Vertical Storage Tanks, with fixed heat exchanger

Identification and hydraulic connections

| Model | VTC1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1500 | 2000 | 2500/3000 |

| Heat exchanger | ||||||||||

| Inlet | N6 | 11/4" | 11/2" | |||||||

| Outlet | N8 | 11/4" | 11/2" | |||||||

| Sanitary water | ||||||||||

| Inlet cold | N9 | 3/4" | 1” | 11/4" | 11/2" | |||||

| Outlet hot | N5 | 3/4" | 1” | 11/4" | 11/2" | |||||

| Circulation N7 | N7 | 3/4" | 1” | 11/4" | 11/2" | |||||

| Model VTC2 | 11/2" | |||||||||

| Capacity | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1500 | 2000 | 3000 |

| Heat exchanger | ||||||||||

| Inlet lower | N9 | 11/4" | 11/2" | |||||||

| Outlet lower | N10 | 11/4" | 11/2" | |||||||

| Inlet upper | N6 | 11/4" | 11/2" | |||||||

| Outlet upper | N8 | 11/4" | 11/2" | |||||||

| Sanitary water | ||||||||||

| Inlet cold | N11 | 3/4" | 1” | 11/4" | 11/2" | |||||

| Outlet hot | N5 | 3/4" | 1” | 11/4" | 11/2" | |||||

| Circulation | N7 | 3/4" | 1” | 11/4" | 11/2" | |||||

| Model | VTC1/VTC2 | |||||||||

| Various | ||||||||||

| Anode Magnesium | N10/N12 | 11/4" | ||||||||

| Thermometer | N1 | 1/2" | ||||||||

| Sensors | N4-N13 | 1/2" | ||||||||

| Electrical back-up | N2 | 11/2" | 2" | |||||||

| Cleaning flange | N3 | 4" | 5" |

Vertical Storage Tanks, with fixed heat exchanger

Heat exchanger technical characteristics

| Model | VTC1 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Storage Capacity,lit | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Exchanger content ,lit | 13 | 14 | 15.6 | 22 | 22 | 27 | 27 | 35 | 42 | 63 | 63 |

| Exchanger surface area,m² | 1.46 | 1.6 | 1.8 | 2.46 | 2.46 | 2.97 | 2.97 | 3.86 | 4.65 | 7.2 | 7.2 |

| Exchanger flow rate,m³/h | 5 | 5 | 6.5 | 6.5 | 6.5 | 8 | 8 | 9.5 | 9.5 | 9.5 | 9.5 |

| Pressure drop of Heat Exh.mbar | 10 | 12 | 17 | 22 | 22 | 38 | 38 | 48 | 66 | 97 | 97 |

| Thermal loss *,Kwh/24h | 1.16 | 1.72 | 1.94 | 2.15 | 2.8 | 3.9 | 5.23 | 6.65 | 7.19 | 9.71 | 11.13 |

* At Storage water temperature 60 °C and Ambient temperature 20 °C

| Storage Capacity,lit | 200 | 30 | 400 | 500 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Lower Exchanger content ,lit | 9 | 12 | 13 | 22 | 22 | 27 | 27 | 35 | 42 | 63 | 63 |

| Upper Exchanger content,lit | 7 | 8 | 9 | 13 | 13 | 14 | 14 | 18 | 20 | 31 | 31 |

| Lower Exchanger surface area,m² | 1.02 | 1.3 | 1.46 | 2.46 | 2.46 | 2.97 | 2.97 | 3.86 | 4.65 | 7.2 | 7.2 |

| Upper Exchanger surface area, m² | 0.73 | 0.9 | 1.02 | 1.46 | 1.46 | 1.58 | 1.58 | 1.86 | 2.26 | 3.5 | 3.5 |

| Lower Exchanger flow rate,m³/h | 5 | 5 | 6.5 | 6.5 | 6.5 | 8 | 8 | 9.5 | 9.5 | 9.5 | 9.5 |

| Upper Exchanger flow rate,m³/h | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 8 | 8 |

| Pressure drop of L. Heat Exh.mbar | 10 | 12 | 19 | 22 | 22 | 38 | 38 | 48 | 66 | 97 | 97 |

| Pressure drop of U. Heat Exh.mbar | 2 | 4 | 6.5 | 8 | 8 | 12 | 12 | 19 | 22 | 33 | 33 |

| Thermal loss *,Kwh/24h | 1.16 | 1.72 | 1.94 | 2.15 | 2.8 | 3.9 | 5.23 | 6.65 | 7.19 | 9.71 | 11.13 |

* At Storage water temperature 60 °C and Ambient temperature 20 °C

| Model VTC1/VTC2 | H. Exchanger Inlet temperature,°C | H. Exchanger Power**,Kw | Hot Water Supply,L/h | Upper H. Exch.Power**,Kw | Hot Water Supply,L/h |

|---|---|---|---|---|---|

| 200 | 70 | 32,6 | 560 | 17.4 | 300 |

| 80 | 51.7 | 890 | 22.1 | 380 | |

| 90 | 62.2 | 1070 | 36.6 | 630 | |

| 300 | 70 | 34.3 | 590 | 20.9 | 360 |

| 80 | 54.1 | 930 | 32.5 | 560 | |

| 90 | 70.9 | 1220 | 45.3 | 780 | |

| 400 | 70 | 36.9 | 635 | 23.8 | 410 |

| 80 | 57.0 | 980 | 42.4 | 730 | |

| 90 | 75.0 | 1290 | 54.1 | 930 | |

| 500&600 | 70 | 42.2 | 725 | 25.6 | 440 |

| 80 | 65.1 | 1120 | 44.8 | 770 | |

| 90 | 87.8 | 1510 | 57 | 980 | |

| 800&1000 | 70 | 48.3 | 830 | 32 | 550 |

| 80 | 81.4 | 1400 | 54.1 | 930 | |

| 90 | 102.3 | 1760 | 66.9 | 1150 | |

| 1500 | 70 | 56.4 | 970 | 37 | 635 |

| 80 | 95.3 | 1640 | 57 | 980 | |

| 90 | 120.3 | 2080 | 75 | 1290 | |

| 2000 | 70 | 63.3 | 1090 | 42.1 | 725 |

| 80 | 107 | 1840 | 65.1 | 1120 | |

| 90 | 138.4 | 2380 | 85.5 | 1470 | |

| 2500&3000 | 70 | 69.7 | 1200 | 52.9 | 910 |

| 80 | 127.9 | 2200 | 71.5 | 1230 | |

| 90 | 175.8 | 3020 | 122.1 | 2100 |

Type Model

Electrical water heater EVT

In some applications where the electrical energy is the only possible or preferable source for water heating,

EVT electrical vertical water heaters standard capacities up to 3000Lit are used with the following specifications:

- Material of tank Low carbon hot rolled steel plate DIN EN 10111-98 DD 11

- Internal protection Enamel coating, thickness 200µm-250µm

- Working pressure 10 bar

- Testing pressure 13 bar

- Max working temp 95°C

- Extra Protection Magnesium rod

- Insulation Free CFC Polyurethane, density 44 kg/m³

- Insulation thickness 50mm PU for 200-600 lit 80mm Foam Soft PU for 800-3000 lit

- Outer jacket Artificial Leather Cover, painted steel cover upon request

- Electrical heating elem. Stainless steel, capacity (Kw) upon customer’s request

(capacity range 2….45Kw) 230 - 230/380V

Features:

The control box is fixed at the water heater, made of Polyester with degree of protection IP54. Three electrical heating

elements are operating by electro-magnet contactors signal from thermostats or individually by manual external

disconnecting switches. The control box contains one main input fuse, safety thermostats and power pilot lights.

| Model | EVT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Effective capacity,Lit | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Total Height(H),mm | 1320 | 1210 | 1450 | 1800 | 2040 | 2100 | 2070 | 2300 | 2230 | 2220 | 2540 |

| Total Dia.(D),mm | 590 | 700 | 750 | 750 | 750 | 900 | 1000 | 1120 | 1260 | 1460 | 1460 |

| Net weight,Kg | 75 | 92 | 126 | 148 | 162 | 226 | 251 | 346 | 403 | 490 | 550 |